|

Molding Processes

ZāGO Manufacturing Company is committed

to superior craftsmanship in making the

best products available with all

manufacturing done in the U.S.A.

To produce our industry-leading line of

sealing switch boots, we begin by

purchasing raw silicone rubber ZZR 765

Class 3A in a natural/clear color or

off-white. This rubber is thoroughly

tested by our quality control department

and then stored in a low temperature

environment. When an order is received,

our production team selects the rubber

that matches the customer’s

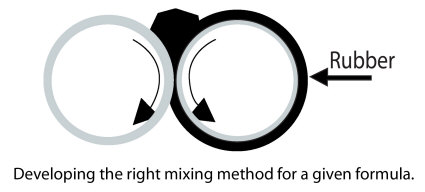

specifications. Our technicians then

re-compound the rubber into its final

stage by adding coloring or other final

additives as requested. The material is

then fed through a rubber mill mixing

machine that combines all the

ingredients from the “recipe” to achieve

a final elastomer. When the batch is

finished, it is assigned a lot number

and a date to ensure proper shelf life.

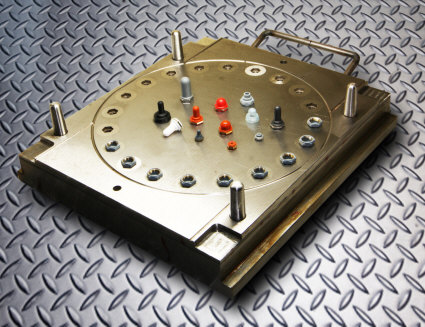

We then slice the rubber to the required

weight and thickness and prepare to mold

the part utilizing Wabash compression or

transfer molding process machines.

ZāGO is committed to investing in

the future

of manufacturing in America.

CUSTOMER TESTIMONIALS

|