|

Specifications

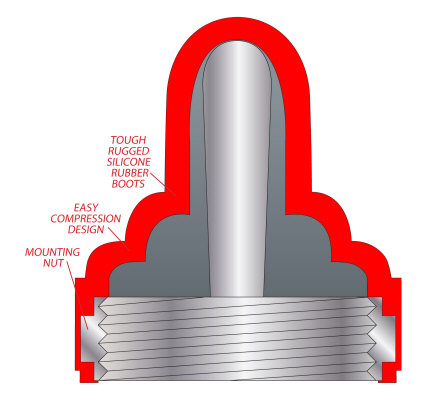

Material:

Military

– Silicone Rubber in accordance with

A-A-59588 Class 3a, grades 30, 50, or

60. Standard color is gray. Other colors

are available upon request.

Commercial

– High Strength silicone rubber, grades

30, 50 or 60.

Mounting Nut:

Corrosion resistant – Nickel Plated

Brass

Design and Construction:

Boots are designed and constructed to

the physical dimensions specified. All

threaded parts shall be in accordance

with FED-STD-H28 unless otherwise

specified.

Temperature Range:

-93 F to +400 F

Pressure Range:

15 psi internal and 15 psi external

Military Specification:

Meets MIL-B-5423

Ingress Rating:

IP68

Shelf Life:

25 Years (depending on environment)

Specifications are written and applied

with the intent of guaranteeing product

performance. Specifications can be

written by the customer for the rubber

parts they are buying, but are often

derived from a formal system developed

by a technical association, such as the

SAE (Society of Automotive Engineers), a

government or military organization or

the commonly applied commercial standard

from ASTM (D-2000). International

standard requirements are also

commonplace.

Specifications for rubber products

generally include physical and chemical

tests for the compound. These may be

relatively limited, such as basic levels

of hardness, tensile strength,

elongation, and resistance to oils

and/or heat. These requirements may be

expanded to include a variety of tests,

such as compression set, flame

resistance, low temperature resistance,

special fluid or chemical exposure,

toxicity evaluations, and more. The

specification spells out what tests have

to be done to qualify the product or

process initially. The customer may

require frequent re-testing of some or

all of the initial tests to create

confidence in the product.

While specifications are negotiable

between the customer and the supplier,

superior compound properties and a high

frequency of re-testing may result

in higher costs to produce the finished

product.

CUSTOMER TESTIMONIALS

|