| |

|

|

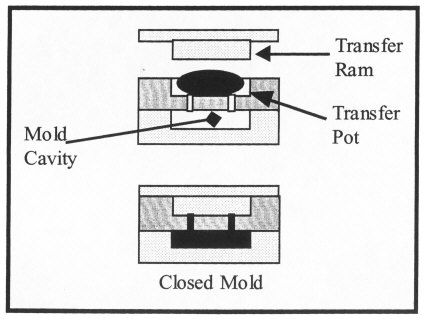

Transfer Molding

In a transfer mold procedure, the mold

is removed from the press and opened.

First, a metal insert is placed into the

cavity, and then a pre-cut piece of

uncured rubber of pre-determined weight

is placed into the transfer “pot.” The

loaded mold is then placed back into the

press and the press is then closed. The

pressure forcing the plates together

distributes or transfers the pre-cut

piece of uncured rubber in the “pot”

down through the “sprues” and into the

cavities. The uncured rubber is then

forced into the shape of the cavity in

the mold. An excess of material flows

out of the cavity along the gates and

vents. The mold remains closed until the

rubber is cured, completing the cycle.

Unlike compression molds, transfer molds

consume additional rubber when filling

the cavity in the “pot” and “sprues.”

Because the cavity plates start out

closed, however, less rubber escapes the

cavity thereby limiting excess flash.

This also makes it well-suited for

molding delicately shaped parts and

securing inserts that are embedded in a

product. Since you work with a single

piece of uncured rubber and not several

individual pre-cut or shaped pieces of

rubber for each cavity, the transfer

mold is ideal for colored and

translucent compounds. Transfer molds

have a shorter cycle and cure time than

compression molds. This is due to the

rapid transfer of heat to the rubber

while being forced from the “pot”

through the “sprue” and into the cavity.

It is also faster to load just one piece

of rubber when running a multi-cavity

mold. Due to the more complex design of

a transfer mold, it is more expensive to

purchase than a compression mold, but it

may be better suited for your product

design.

CUSTOMER TESTIMONIALS

|

|